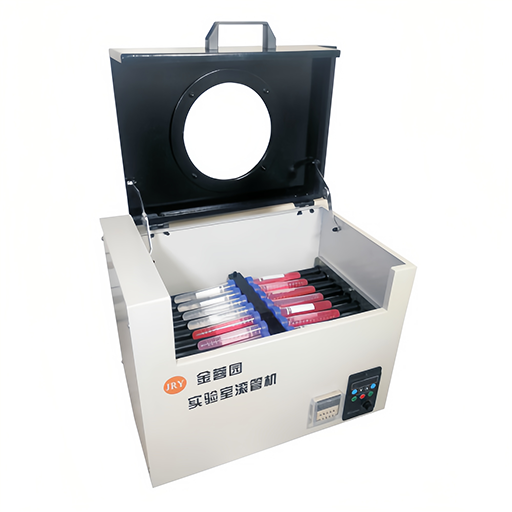

Bottle roller machine

The laboratory bottle roller machine JRY-GP combines laboratory stirring, mixing, ball milling, washing, polishing, drying and other functions. It not only reduces the labor intensity of scientific researchers and improves work efficiency, but also reduces occupational hazards such as laboratory dust and harmful gases.

Product Details

The laboratory bottle roller machine JRY-GP combines laboratory stirring, mixing, ball milling, washing, polishing, drying and other functions. It not only reduces the labor intensity of scientific researchers and improves work efficiency, but also reduces occupational hazards such as laboratory dust and harmful gases.

▮ Performance and Features of the JRY-GP

◾ A laboratory bottle roller machine places one or more samples in a sealed roller bottle and uses the rapid rolling motion of the bottle to achieve stirring, mixing, ball milling, washing, polishing, and drying. It is an indispensable piece of equipment for materials, chemistry, biology, environmental, or third-party testing laboratories. It offers a wide variety of roller bottles and sample holders and offers a high cost-effectiveness.

◾ Compared to magnetic stirring, the laboratory bottle roller machine boasts larger sample volumes and more uniform mixing. Steel or agate beads can be added to the roller bottle to enhance the stirring effect. Compared to motor stirring, the sample can be fully sealed. Disposable plastic roller bottles can be used, eliminating the need for cleaning the motor. The stirring function of a laboratory bottle roller machine is an excellent choice for labs specializing in coatings, graphene slurries, new energy materials, and soil science.

◾ Sample uniformity is extremely important in materials and testing labs. The mixing function of a laboratory bottle roller machine is suitable not only for liquid mixing but also for powders and slurries.

◾ The washing, polishing and drying principles of the laboratory bottle roller machine are similar to those mentioned above. The main features are that the roller bottles are corrosion-resistant, the metal ion background of the plastic roller bottles is extremely low, the working process is fully sealed and does not produce odor, the operation is simple, and the temperature and speed control are precise.